| Classification | AWS A5.5, E9015-B9 |

|---|---|

| Form | Welding Electrode, Welding Rods |

| Type Of Current | Direct Current Electrode Positive (DCEP) |

| Diameters | 3/32”, 1/8”, 5/32”, 3/16” or 2.5mm, Ø 3.2mm, Ø 4.0mm, Ø 5.0mm |

| Size | 2.0mm ∞ 5.0mm |

| AC/DC+ | 50-80, 80-110, 100-135, 140-180 |

| Welding Positions | All positions 5/32” & 3/16” recommended for use in flat & horizontal positions only (F, V, OH, H) |

| AWS A5.5, E9015-B9 Coated Electrodes Application & uses |

|

- 1st Dubhash Lane, Girgaon,

Mumbai-400004

- +91-9920631634

+91 98200 31634

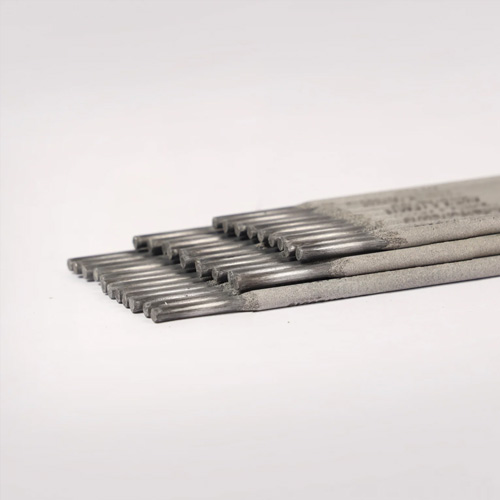

E9015-B9 Welding Electrodes

The E9015-B9 Welding Electrodes from Metals And Welding Specialities are engineered for high-performance welding applications that demand superior strength, heat resistance, and long-term stability under severe service conditions. These electrodes are formulated to deposit a low-hydrogen weld metal specifically designed for the fabrication and repair of creep-resistant steels used in high-temperature and high-pressure environments. Classified under UNS K90941 and conforming to ASTM A213 Grade T9 / ASTM A335 Grade P9, this electrode meets stringent industry standards for quality and durability.

Table Of Content

- What is E9015-B9 Welding Electrodes?

- Specification of E9015-B9 Welding Electrodes

- Equivalent Grade Of E9015-B9 Welding Electrodes

- Chemical Composition of E9015-B9 Welding Electrodes

- E9015-B9 Welding Electrodes Parameters

- People Searched for E9015-B9 Welding Electrodes

- Supply Cities of E9015-B9 Welding Electrodes

- Export Countries of E9015-B9 Welding Electrodes

Designed for use in power generation plants, petrochemical industries, and refineries, E9015-B9 Welding Electrodes deliver consistent results when joining 9Cr-1Mo alloy steels. These materials are widely used in steam pipes, headers, boilers, and heat exchangers where oxidation and corrosion resistance at elevated temperatures are crucial. The weld deposit provides excellent toughness and high creep strength, maintaining structural integrity even after prolonged exposure to extreme conditions.

The Metals And Welding Specialities E9015-B9 electrodes exhibit a stable arc with smooth metal transfer and minimal spatter, ensuring clean, defect-free welds. Their special low-hydrogen coating reduces the risk of hydrogen-induced cracking and ensures superior weld metal integrity. The slag is easily removable, contributing to efficient welding operations and higher productivity. These electrodes are particularly suitable for out-of-position welding, making them versatile and reliable for field or shop applications.

For welders working on alloy steels like A182 F9, A199 T9, and similar grades, these electrodes provide exceptional metallurgical compatibility and mechanical properties. The weld metal exhibits tensile strength up to 620 MPa and excellent impact toughness, ensuring reliable performance in demanding service conditions. When properly heat-treated, the deposited weld metal matches the creep strength and ductility of the base metal, which is critical for long-term service reliability in pressure vessel and power plant applications.

E9015-B9 Welding Electrodes in India, E9015-B9 Welding Electrodes Manufacturers in India, E9015-B9 Welding Electrodes Suppliers in India, E9015-B9 Welding Electrodes Stockists in India, E9015-B9 Welding Electrodes Exporters in India

All Metals And Welding Specialities welding consumables, including the AWS Class E9015-B9 electrodes, are manufactured using premium raw materials and undergo rigorous quality control. Each batch is tested to ensure compliance with AWS A5.5 / ASME SFA-5.5 specifications and international welding standards. Our electrodes are packed to maintain low moisture content, guaranteeing consistent performance even in challenging field conditions.

Choosing Metals And Welding Specialities E9015-B9 Coated Electrodes means choosing a product that offers stable arc performance, excellent weld bead appearance, and superior mechanical integrity under thermal stress. Whether used in fabrication, repair, or maintenance, these electrodes are trusted by professionals for their dependability and consistent results in high-temperature service applications.

-

Specification E9015-B9 Welding Electrodes

-

Equivalent Grade Of AWS ENiCrMo-4 Coated Electrodes

Class UNS Oxford Alloys BOHLER E9015-B9 W50425 Alloy 9015-B9 BOHLER FOX C 9 MV -

E9015-B9 Welding Electrodes Chemical Composition

C Mn Si Cr Ni Mo P S N Cb Cu V .09 .97 .20 9.5 .10 .95 .01 .01 .05 .04 .01 .21 -

E9015-B9 Welding Electrodes Parameters

DIAMETER 3/32” 1/8” 5/32” 3/16” AMPS -FLAT 90-110 120-145 155-190 200-235 -OUT OF POSITION 80-105 100-130 145-180 VOLTAGE 22 TO 28 22 TO 28 22 TO 28 22 TO 28

People Also Searched

E9015-B9 welding rod, AWS A5.5 E9015-B9, ASME SFA-5.5 E9015-B9, E9015-B9 electrode specification, 9Cr-1Mo welding electrode, P9 steel electrode, T9 tube welding rod, UNS K90941 filler metal, ASTM A213 T9 welding electrode, ASTM A335 P9 rod, 9Cr-1Mo electrode supplier, high-temperature alloy steel electrodes, creep-resistant welding rods, low hydrogen electrode for Cr-Mo steel, E9015-B9 mechanical properties, E9015-B9 chemical composition, power plant welding rods, boiler tube welding electrode, refinery weld consumables, Cr-Mo welding filler, E9015-B9 weldability, E9015-B9 rod price, Metals And Welding Specialities electrodes, alloy steel welding consumables, P9 welding electrode, 9Cr1Mo electrode for pressure vessels, E9015-B9 heat treatment, E9015-B9 hardness, E9015-B9 welding parameters, high-strength steel electrode, E9015-B9 vs E8018-B2, AWS E9015-B9 data sheet, E9015-B9 welding current, E9015-B9 applications, ASTM Grade P9 filler metal, UNS K90941 electrode manufacturer, 9Cr-1Mo alloy filler rod, E9015-B9 rod supplier India.

E9015-B9 Welding Electrodes, E9015-B9 Welding Electrodes Manufacturers, E9015-B9 Welding Electrodes Suppliers, E9015-B9 Welding Electrodes Stockists, E9015-B9 Welding Electrodes Exporters