| Classification | AWS A5.9, ER309/309L |

|---|---|

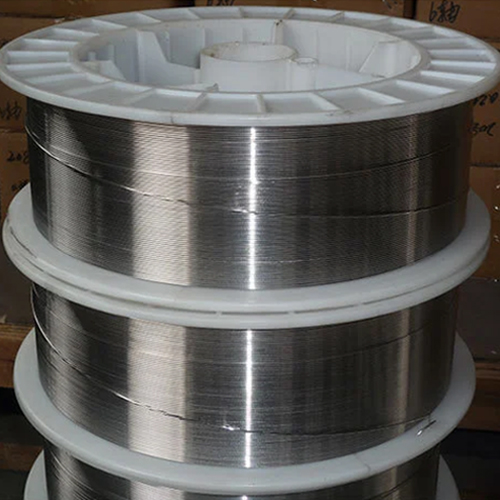

| Form | MIG spools, TIG cut lengths, Reels and Coils |

| Type Of Welding | Inert Gas Welding |

| Current | MIG-DCEP / TIG-DCEN |

| Diameters | .023”, .030”, .035”, .045”, 1/16”, 3/32”, 1/8” |

| Standard TIG straight lengths are available | 36” (914 mm) or 39” (1000 mm) lengths. Other lengths available upon request. |

| AWS A5.9, ER309/309L MIG & TIG Filler Metal Application & uses |

|

- 1st Dubhash Lane, Girgaon,

Mumbai-400004

- +91-9920631634

+91 98200 31634

ER309/309L MIG & TIG Welding Wire

At Metals And Welding Specialities, we manufacture and supply high-quality ER309/309L MIG & TIG Welding Wire welding wires designed for superior performance in joining similar and dissimilar stainless steels. This alloy is formulated with balanced chromium and nickel content, ensuring excellent corrosion and oxidation resistance, even in high-temperature environments. The dual-grade composition of ER309/309L combines the strength of ER309 with the low carbon benefits of ER309L, offering exceptional weld integrity while minimizing carbide precipitation and intergranular corrosion.

Table Of Content

- What is ER309/309L MIG & TIG Welding Wire?

- Specification of ER309/309L MIG & TIG Welding Wire

- Equivalent Grade Of ER309/309L MIG & TIG Welding Wire

- Chemical Composition of ER309/309L MIG & TIG Welding Wire

- ER309/309L MIG & TIG Welding Wire Parameters

- People Searched for ER309/309L MIG & TIG Welding Wire

- Supply Cities of ER309/309L MIG & TIG Welding Wire

- Export Countries of ER309/309L MIG & TIG Welding Wire

Our ER309/309L stainless steel welding wire is classified under UNS S30983 and conforms to ASTM A240 Grade 309L standards, ensuring consistency and reliability in industrial applications. It is widely used in industries such as petrochemical, food processing, chemical manufacturing, and power generation, where resistance to heat and corrosion is essential. This filler metal performs exceptionally when welding stainless steel to mild steel or carbon steel, maintaining high strength and crack resistance across varying thermal conditions.

ER309/309L MIG wire from Metals And Welding Specialities provides smooth feeding, stable arc performance, and minimal spatter, making it suitable for both automated and manual welding processes. When used in MIG (GMAW) and TIG (GTAW) applications, it delivers a clean, stable weld bead with outstanding slag detachability. The low carbon content (L-grade) effectively prevents sensitization, making it ideal for components that operate under prolonged thermal exposure or cyclic heating conditions.

The weld deposits from ER309/309L TIG wire exhibit superior mechanical properties, including high tensile strength and good ductility. It is a preferred choice for cladding carbon steel with stainless steel, welding buffer layers before hardfacing, and fabricating equipment that must endure extreme service conditions. Its excellent oxidation resistance up to 1000°C (1832°F) ensures durability and reliability, even in harsh environments where standard stainless steels might fail.

ER309/309L MIG & TIG Welding Wire in India, ER309/309L MIG & TIG Welding Wire Manufacturers in India, ER309/309L MIG & TIG Welding Wire Suppliers in India, ER309/309L MIG & TIG Welding Wire Stockists in India, ER309/309L MIG & TIG Welding Wire Exporters in India

At Metals And Welding Specialities, each batch of ER309/309L filler wire undergoes rigorous quality testing to meet international standards and ensure consistent performance. Our advanced manufacturing facilities and stringent quality assurance systems guarantee that every spool and coil meets the highest specifications for weld purity, strength, and finish. With Metals And Welding Specialities, customers can rely on unmatched product integrity, technical expertise, and dependable supply for all their stainless-steel welding needs.

-

Specification ER309/309L MIG & TIG Welding Wire

-

Equivalent Grade Of AWS ERCuNi MIG & TIG

Class UNS Oxford Alloys SANDVIK BOHLER ER309/309L S30983 Alloy 309/309L EXATON 22.15.3.L BOHLER THERMAINT 25/14 E-309L -

ER309/309L MIG & TIG Welding Wire Chemical Composition

C Cr Ni Mo Mn Si P S Cu 0.03 23.0-25.0 12.0-14.0 0.75 1.0-2.5 0.30-0.65 0.03 0.03 0.75 -

ER309/309L MIG & TIG Welding Wire Parameters

Diameter Process Volt Amps Shielding Gas in (mm) .035 (0.9) GMAW 22-23 180-210 Spray transfer 98% Argon/2% Oxygen .045 (1.2) GMAW 23-25 195-260 Spray transfer 98% Argon/2% Oxygen 1/16 (1.6) GMAW 25-28 260-390 Spray transfer 98% Argon/2% Oxygen .035 (0.9) GMAW 19-23 55-170 Short Circuiting Transfer 90% Helium/ 7 ½% Argon / 2 ½% CO2 .045 (1.14) GMAW 19-23 100-185 Short Circuiting Transfer 90% Helium/ 7 ½% Argon / 2 ½% CO2 .035 (0.9) GTAW 12-15 60-100 100% Argon .045 (1.14) GTAW 13-16 70-120 100% Argon 1/16 (1.6) GTAW 14-16 90-130 100% Argon 3/32 (2.4) GTAW 15-20 120-175 100% Argon 1/8 (3.2) GTAW 16-20 150-220 100% Argon

People Also Searched

ER309/309L welding wire, ER309L MIG wire, ER309L TIG filler rod, AWS ER309L wire specification, UNS S30983 filler metal, ASTM A240 Grade 309L, ER309 vs ER309L, 309L stainless steel wire price, ER309L welding applications, ER309L stainless steel welding rod, ER309L composition, ER309L chemical properties, ER309L mechanical strength, ER309L corrosion resistance, ER309L oxidation resistance, ER309L filler wire supplier, ER309L stainless steel filler, ER309L welding rod manufacturer, ER309L TIG wire uses, ER309L MIG wire data sheet, ER309L UNS number, ER309L ASTM standard, ER309/309L stainless filler wire, ER309L wire for dissimilar joints, ER309L stainless to carbon steel welding, ER309L high-temperature resistance, ER309L nickel-chromium filler, ER309L industrial welding wire, ER309L welding performance, ER309L wire manufacturer India, Metals And Welding Specialities, ER309L wire, ER309L export quality filler wire, ER309L stainless steel wire specification, ER309L stainless welding consumables, ER309L for heat-resistant joints, ER309L stainless cladding wire, ER309L low carbon stainless filler

ER309/309L MIG & TIG Welding Wire, ER309/309L MIG & TIG Welding Wire Manufacturers, ER309/309L MIG & TIG Welding Wire Suppliers, ER309/309L MIG & TIG Welding Wire Stockists, ER309/309L MIG & TIG Welding Wire Exporters