| Classification | AWS A5.14, ERNiCrMo-13 |

|---|---|

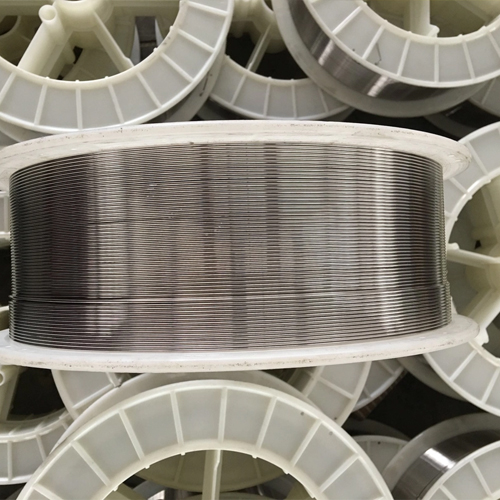

| Form | MIG spools, TIG cut lengths, Reels and Coils |

| Type Of Welding | Inert Gas Welding |

| Standard TIG straight lengths are available | 36” (914 mm) or 39” (1000 mm) lengths. Other lengths available upon request. |

| AWS ERNiCrMo-12 MIG & TIG Filler Metal Application & uses |

|

- 1st Dubhash Lane, Girgaon,

Mumbai-400004

- +91-9920631634

+91 98200 31634

ERNiCrMo-13 MIG & TIG

Metals And Welding Specialities proudly offers ERNiCrMo-13 MIG & TIG, a high-performance nickel-chromium-molybdenum alloy wire engineered for superior corrosion resistance and weldability. Classified under UNS N06025 and conforming to ASTM A494 Grade CW6M, this filler metal is designed for critical welding operations where strength, durability, and corrosion protection are essential. Known by its Universal Standard name Alloy 625, this product meets the demanding requirements of industries operating in harsh chemical and marine environments.

Table Of Content

- What is ERNiCrMo-13 MIG & TIG?

- Specification of ERNiCrMo-13 MIG & TIG

- Equivalent Grade Of AWS ERNiCrMo-4 MIG & TIG

- Chemical Composition of ERNiCrMo-4 MIG & TIG

- ERNiCrMo-13 MIG & TIG Parameters

- People Searched for Class ERNiCrMo-4 MIG & TIG

- Supply Cities of ERNiCrMo-13 MIG & TIG

- Export Countries of ERNiCrMo-13 MIG & TIG

The ERNiCrMo-13 welding wire from Metals And Welding Specialities delivers exceptional performance in gas tungsten arc welding (GTAW/TIG) and gas metal arc welding (GMAW/MIG) applications. It provides a stable arc, smooth weld bead, and minimal spatter, ensuring clean, high-quality welds. Its composition, rich in nickel, chromium, and molybdenum, offers remarkable resistance to oxidation, crevice corrosion, and stress-corrosion cracking even at elevated temperatures. This makes it the preferred choice for joining nickel-chromium-molybdenum alloys, stainless steels, and dissimilar metals in high-temperature systems.

Engineers and fabricators rely on ERNiCrMo-13 for use in chemical processing plants, offshore platforms, power generation facilities, and pollution control equipment. Its robust metallurgical stability ensures excellent mechanical properties under cyclic thermal stress and corrosive conditions. The filler metal performs exceptionally in environments containing chlorides, acids, and other aggressive chemicals that typically deteriorate conventional materials. Its resistance to pitting and localized corrosion makes it a go-to material for pressure vessels, heat exchangers, and piping systems exposed to seawater and acidic solutions.

Produced under strict quality controls, Metals And Welding Specialities’ ERNiCrMo-13 MIG & TIG wires ensure consistent diameter, clean surface finish, and precise chemical composition for optimal weld integrity. The wire’s low carbon content minimizes carbide precipitation during welding, preserving the corrosion resistance of the weld metal. This property also makes it ideal for overlay and cladding operations where long-term protection against corrosion and wear is critical.

ERNiCrMo-13 MIG & TIG in India, ERNiCrMo-13 MIG & TIG Manufacturers in India, ERNiCrMo-13 MIG & TIG Suppliers in India, ERNiCrMo-13 MIG & TIG Stockists in India, ERNiCrMo-13 MIG & TIG Exporters in India

As a trusted manufacturer and supplier, Metals And Welding Specialities delivers this high-quality welding consumable in various spool and packaging options to meet diverse industrial requirements. Whether for fabrication, maintenance, or repair work, our ERNiCrMo-13 TIG & MIG wires provide unmatched reliability, ensuring long service life and reduced downtime. Every batch undergoes rigorous testing to confirm mechanical strength, microstructural integrity, and corrosion performance, making it one of the most dependable products in the market for nickel alloy welding applications.

Choose Metals And Welding Specialities for consistent quality, technical precision, and expert support with ERNiCrMo-13 MIG & TIG filler metals — your trusted solution for advanced corrosion-resistant welding.

-

Specification ENiCrFe-2 Coated Electrodes

-

Equivalent Grade Of AWS ENiCrFe-2 Coated Electrodes

Class UNS Oxford Alloys SANDVIK BOHLER UTP ESAB ERNiCrMo-13 N06059 Alloy 59 EXATON NI 59 BOHLER THERMANIT NIMO C24 UTP A 759 OK AUTROD NICRMO-13 -

ENiCrFe-2 Coated Electrodes Chemical Composition

C Mn Fe P S Si Cu Ni Co Cr Mo V W Other 0.02 1.0 4.0-7.0 0.04 0.03 0.08 0.50 Rem 2.5 14.5-16.5 15.0-17.0 0.35 3.0-4.5 0.5 -

ENiCrFe-2 Coated Electrodes Parameters

Diameter Process Volt Amps Shielding Gas In mm 0.035 0.9 GMAW 26-29 150-190 Spray Transfer 100% Argon 0.045 1.2 GMAW 28-32 180-220 1/16 1.6 GMAW 29-33 200-250 1/16 1.6 GTAW 14-18 90-130 100% Argon 3/32 2.4 GTAW 15-20 120-175 100% Argon 1/8 3.2 GTAW 15-20 150-220 100% Argon

People Also Searched

ERNiCrMo-13 filler metal, ERNiCrMo-13 MIG wire, ERNiCrMo-13 TIG wire, Alloy 625 welding wire, UNS N06025 welding rod, ASTM A494 CW6M filler wire, nickel alloy welding wire, corrosion-resistant filler metal, nickel-chromium-molybdenum alloy wire, ERNiCrMo-13 chemical composition, Alloy 625 TIG filler, MIG wire for Alloy 625, nickel-based welding consumables, ERNiCrMo-13 applications, Metals And Welding Specialities welding wire, ERNiCrMo-13 price, ERNiCrMo-13 suppliers, ERNiCrMo-13 density, AWS A5.14 ERNiCrMo-13, ERNiCrMo-13 mechanical properties, high-temperature welding wire, chemical plant welding wire, marine welding consumables, heat exchanger welding wire, pressure vessel welding filler, offshore welding wire, nickel alloy TIG rod, MIG wire for dissimilar metals, oxidation-resistant filler wire, ERNiCrMo-13 corrosion resistance, Alloy 625 UNS N06025, ERNiCrMo-13 welding data, ERNiCrMo-13 UNS number, ASTM Grade CW6M wire, ERNiCrMo-13 welding performance, Metals And Welding Specialities ERNiCrMo-13, Alloy 625 welding filler, ERNiCrMo-13 specification, ERNiCrMo-13 wire.

ERNiCrMo-13 MIG & TIG, ERNiCrMo-13 MIG & TIG Manufacturers, ERNiCrMo-13 MIG & TIG Suppliers, ERNiCrMo-13 MIG & TIG Stockists, ERNiCrMo-13 MIG & TIG Exporters