| Classification | AWS A5.9, ER310 |

|---|---|

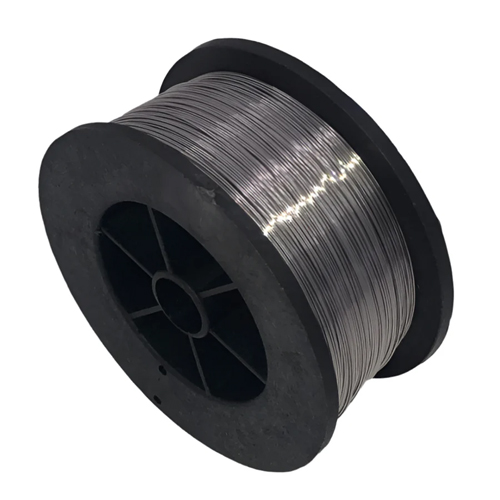

| Form | MIG spools, TIG cut lengths, Reels and Coils |

| Type Of Welding | Inert Gas Welding |

| Current | MIG-DCEP / TIG-DCEN |

| Diameters | .023”, .030”, .035”, .045”, 1/16”, 3/32”, 1/8” |

| Standard TIG straight lengths are available | 36” (914 mm) or 39” (1000 mm) lengths. Other lengths available upon request. |

| AWS ER310 MIG & TIG Filler Metal Application & uses |

|

- 1st Dubhash Lane, Girgaon,

Mumbai-400004

- +91-9920631634

+91 98200 31634

ER316/316H MIG & TIG Welding Wire

ER316/316H MIG & TIG Welding Wire welding wire, offered by Metals And Welding Specialities, is a premium-grade stainless steel filler metal designed for superior corrosion resistance, high-temperature performance, and excellent weld integrity. Manufactured to meet AWS A5.9 ER316/316H specifications, this alloy combines strength and stability for both MIG (GMAW) and TIG (GTAW) welding applications. The product adheres to UNS S31603/S31609 and corresponds to ASTM A240 Type 316/316H standards, ensuring top-quality consistency and compatibility across industrial welding operations.

Table Of Content

- What is ER316/316H MIG & TIG Welding Wire?

- Specification of ER316/316H MIG & TIG Welding Wire

- Equivalent Grade Of ER316/316H MIG & TIG Welding Wire

- Chemical Composition of ER316/316H MIG & TIG Welding Wire

- ER316/316H MIG & TIG Welding Wire Parameters

- People Searched for ER316/316H MIG & TIG Welding Wire

- Supply Cities of ER316/316H MIG & TIG Welding Wire

- Export Countries of ER316/316H MIG & TIG Welding Wire

With a balanced chemical composition of chromium, nickel, and molybdenum, ER316/316H wire provides outstanding resistance to pitting, crevice corrosion, and intergranular attack in chloride-rich and acidic environments. Its low carbon content in ER316 and stabilized high-carbon version ER316H make it suitable for both cryogenic and elevated temperature conditions. This filler wire delivers smooth arc stability, minimal spatter, and clean weld beads, making it a trusted choice for fabricators working on chemical processing equipment, pressure vessels, heat exchangers, and food-grade piping systems.

The AWS ER316/316H alloy is specifically engineered for joining stainless steels of similar composition, such as 316, 316L, 316H, and their cast equivalents. It maintains high tensile and creep strength even under prolonged thermal exposure, offering extended service life in high-stress environments. Its superior slag detachability and consistent wire feed performance make it suitable for automated and semi-automatic welding operations. The inclusion of molybdenum enhances corrosion resistance against seawater and acidic media, while the higher carbon content in ER316H provides added strength retention at elevated temperatures.

At Metals And Welding Specialities, every spool and batch of ER316/316H MIG & TIG wire undergoes rigorous testing to ensure metallurgical integrity and compliance with international standards. Our production facilities maintain strict quality control to guarantee optimal wire diameter uniformity, precise chemistry, and dependable mechanical properties. Whether used in marine fabrication, petrochemical plants, pharmaceutical equipment, or food processing facilities, this welding wire ensures reliable performance and defect-free joints.

ER316/316H MIG & TIG Welding Wire in India, ER316/316H MIG & TIG Welding Wire Manufacturers in India, ER316/316H MIG & TIG Welding Wire Suppliers in India, ER316/316H MIG & TIG Welding Wire Stockists in India, ER316/316H MIG & TIG Welding Wire Exporters in India

As a versatile stainless steel filler metal, ER316/316H MIG & TIG wire combines weldability, strength, and resistance in one solution. Professionals across industries rely on it for critical applications that demand both corrosion protection and long-term durability. Choose Metals And Welding Specialities for a welding wire that meets the toughest specifications, performs under pressure, and delivers consistent, high-quality results every time.

For optimal results, use ER316/316H filler wire with argon or argon-based shielding gases to ensure smooth, stable arcs and superior penetration. Its unique metallurgical composition prevents dilution effects that typically reduce strength in mixed-metal welds. When durability, safety, and performance are non-negotiable, ER316/316H stands as a dependable solution engineered to exceed expectations in demanding welding environments.

-

Specification ER316/316H MIG & TIG Welding Wire

-

Equivalent Grade Of AWS ERCuNi MIG & TIG

Class UNS Oxford Alloys BOHLER ER310 S31080 Alloy 310 BOHLER THERMAINT 310 -

ER316/316H MIG & TIG Welding Wire Chemical Composition

C Cr Ni Mo Mn Si P S Cu 0.08-0.15 25.0-28.0 20.0-22.5 0.75 1.0-2.5 0.30-0.65 0.03 0.03 0.75 -

ER316/316H MIG & TIG Welding Wire Parameters

Diameter Process Volt Amps in (mm) .035 (0.9) GTAW 12-15 60-90 .045 (1.14) GTAW 13-16 80-110 1/16” (1.6) GTAW 14-16 90-130 3/32” (2.4) GTAW 15-20 120-175

People Also Searched

ER316/316H welding wire, AWS A5.9 ER316, UNS S31603, UNS S31609, ASTM A240 316, 316H stainless filler metal, stainless steel MIG wire, stainless TIG wire, 316 welding rod, 316H TIG filler, GMAW stainless wire, GTAW filler metal, corrosion-resistant welding wire, molybdenum stainless filler, 316 vs 316H difference, 316L welding wire, heat-resistant stainless filler, marine-grade stainless wire, chemical plant welding rod, food-grade stainless welding, ER316H wire supplier, stainless steel filler metal specification, AWS ER316 mechanical properties, TIG filler wire for pressure vessels, stainless welding consumables, MIG filler wire 316H, 316H wire for high temperature, stainless steel pipe welding wire, austenitic stainless filler, ER316 chemical composition, stainless filler for heat exchangers, industrial welding consumables, stainless wire for petrochemical use, ER316H vs ER316L, stainless steel alloy filler, 316 stainless TIG electrode, precision stainless filler wire.

ER316/316H MIG & TIG Welding Wire, ER316/316H MIG & TIG Welding Wire Manufacturers, ER316/316H MIG & TIG Welding Wire Suppliers, ER316/316H MIG & TIG Welding Wire Stockists, ER316/316H MIG & TIG Welding Wire Exporters