| Classification | AWS A5.9, ER385 |

|---|---|

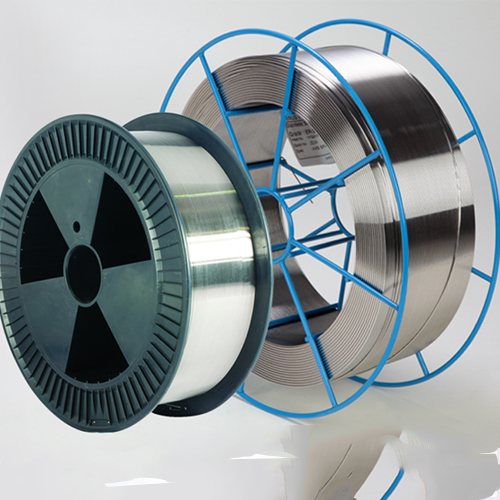

| Form | MIG spools, TIG cut lengths, Reels and Coils |

| Type Of Welding | Inert Gas Welding |

| Current | MIG-DCEP / TIG-DCEN |

| Diameters | .023”, .030”, .035”, .045”, 1/16”, 3/32”, 1/8” |

| Standard TIG straight lengths are available | 36” (914 mm) or 39” (1000 mm) lengths. Other lengths available upon request. |

| AWS ER385 MIG & TIG Filler Metal Application & uses |

|

- 1st Dubhash Lane, Girgaon,

Mumbai-400004

- +91-9920631634

+91 98200 31634

ER385 MIG & TIG Welding Wire

At Metals And Welding Specialities, we supply high-quality ER385 MIG & TIG Welding Wire, engineered for superior corrosion resistance and long-lasting performance in demanding environments. Designed for precision fabrication and maintenance work, this austenitic stainless steel filler metal is ideal for welding alloys of similar composition, offering exceptional protection against a wide range of corrosive agents including sulfuric, phosphoric, and nitric acids.

Table Of Content

- What is ER385 MIG & TIG Welding Wire?

- Specification of ER385 MIG & TIG Welding Wire

- Equivalent Grade Of ER385 MIG & TIG Welding Wire

- Chemical Composition of ER385 MIG & TIG Welding Wire

- ER385 MIG & TIG Welding Wire Parameters

- People Searched for ER385 MIG & TIG Welding Wire

- Supply Cities of ER385 MIG & TIG Welding Wire

- Export Countries of ER385 MIG & TIG Welding Wire

The ER385 welding wire corresponds to UNS S38500, and its ASTM Grade classification falls under ASTM A240 standards. This universal stainless filler is widely recognized as Alloy 904L, known for its high nickel and molybdenum content that provides outstanding pitting resistance in chloride-rich conditions. It is the go-to choice for industries that operate in highly aggressive chemical and marine atmospheres where durability and weld integrity are paramount.

Metals And Welding Specialities ensures every spool of ER385 MIG & TIG wire meets strict quality and chemical composition standards. The wire’s balanced structure minimizes the risk of intergranular corrosion, even after exposure to elevated temperatures. Its stable arc characteristics and smooth feedability make it suitable for both gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW) processes. This versatility makes it an excellent match for critical applications in chemical processing plants, heat exchangers, pressure vessels, desalination equipment, and marine structures.

Thanks to its superior alloy balance of chromium, nickel, molybdenum, and copper, AWS ER385 maintains excellent resistance to stress corrosion cracking and crevice attack. Its performance surpasses conventional stainless grades such as 316L and 317L, particularly in environments containing high concentrations of halides or strong acids. Fabricators rely on this filler metal to ensure structural integrity and clean, defect-free welds that meet the toughest specifications in global manufacturing standards.

ER385 MIG & TIG Welding Wire in India, ER385 MIG & TIG Welding Wire Manufacturers in India, ER385 MIG & TIG Welding Wire Suppliers in India, ER385 MIG & TIG Welding Wire Stockists in India, ER385 MIG & TIG Welding Wire Exporters in India

At Metals And Welding Specialities, every product undergoes rigorous testing to guarantee compliance with AWS A5.9 specifications. Our expert team provides technical guidance to help you select the right wire diameter, shielding gas combination, and welding parameters for optimal results. Whether you are working on pipeline fabrication, pressure-resistant tanks, or marine repair, our ER385 MIG & TIG wire delivers unmatched reliability and consistency.

Choose Metals And Welding Specialities as your trusted partner for high-grade stainless welding consumables that meet international benchmarks for performance and safety. With ER385, you get more than a filler metal — you get precision-engineered confidence in every weld.

-

Specification ER385 MIG & TIG Welding Wire

-

Equivalent Grade Of AWS ERCuNi MIG & TIG

Class UNS Oxford Alloys SANDVIK BOHLER ER385 S30888 Alloy 385 EXATON 20.25.5.LCU BOHLER THERMAINT 20/25 CU -

ER385 MIG & TIG Welding Wire Chemical Composition

C Cr Ni Mo Mn Si P S Cu Element Amount 0.08 19.0-21.5 9.0-11.0 0.75 1.0-2.5 0.30-0.65 0.03 0.03 0.75 Nb 10XC min/1.0 max -

ER385 MIG & TIG Welding Wire Parameters

Diameter (MM) 2.5 3.2 4.0 5.0 Length (MM) 350 350 400 400 Current (A) 50-70 80-110 130-160 160-200

People Also Searched

ER385 stainless welding wire, Alloy 904L filler metal, UNS S38500 welding rod, ER385 TIG wire suppliers, ER385 MIG welding wire, AWS A5.9 ER385, stainless steel ER385 wire price, 904L TIG filler rod, corrosion resistant welding wire, high nickel welding consumables, molybdenum alloy filler, stainless steel filler wire 904L, ER385 chemical composition, ASTM A240 stainless welding wire, 904L welding electrode, Alloy 904L TIG rod, ER385 1.2mm wire, ER385 GTAW wire, stainless steel welding consumables, marine grade stainless filler wire, ER385 welding data sheet, nickel alloy TIG wire, ER385 MIG wire manufacturers, heat exchanger welding wire, chemical plant welding filler, UNS S38500 material grade, AWS ER385 specification, stainless ER385 rod, Alloy 904L wire exporters, ER385 filler rod mechanical properties, ER385 corrosion resistance data, stainless TIG wire for chemical service, welding filler for chloride resistance, ER385 UNS number, 904L stainless steel MIG wire, ER385 price per kg, stainless TIG filler for marine use.

ER385 MIG & TIG Welding Wire, ER385 MIG & TIG Welding Wire Manufacturers, ER385 MIG & TIG Welding Wire Suppliers, ER385 MIG & TIG Welding Wire Stockists, ER385 MIG & TIG Welding Wire Exporters