| Classification | A5.14 ERNi-1 |

|---|---|

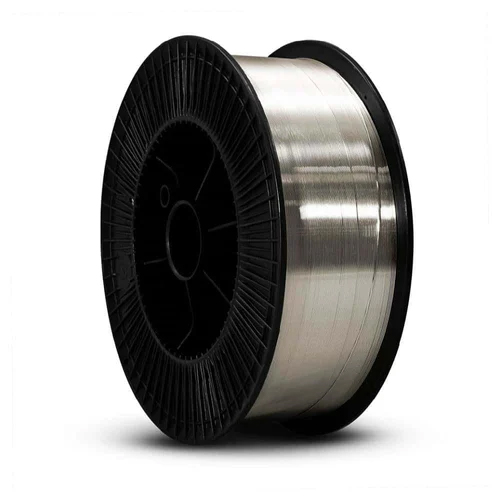

| Form | MIG spools, TIG cut lengths, Reels and Coils |

| Type Of Welding | Inert Gas Welding |

| Standard TIG straight lengths are available | 36” (914 mm) or 39” (1000 mm) lengths. Other lengths available upon request. |

| ERNi-1 MIG & TIG Welding Wire Filler Metal Application & uses |

|

- 1st Dubhash Lane, Girgaon,

Mumbai-400004

- +91-9920631634

+91 98200 31634

ERNi-1 MIG & TIG Welding Wire

The ERNi-1 MIG & TIG Welding Wire welding wire, offered by Metals And Welding Specialities, is a high-quality nickel-based alloy filler metal designed for exceptional corrosion resistance and superior weldability. Engineered with precision, this filler wire corresponds to UNS N02061 and meets the standards of ASTM Grade ERNi-1. It is primarily used for welding wrought or cast nickel materials such as Nickel 200 and Nickel 201. Known for its purity and excellent mechanical strength, this alloy is widely applied across industries that demand reliability in harsh and corrosive environments.

Table Of Content

- What is ERNi-1 MIG & TIG Welding Wire?

- Specification of ERNi-1 MIG & TIG Welding Wire

- Equivalent Grade Of AWS ERNI-1 MIG & TIG

- Chemical Composition of ERNI-1 MIG & TIG

- ERNi-1 MIG & TIG Welding Wire Parameters

- People Searched for Class ERNI-1 MIG & TIG

- Supply Cities of ERNi-1 MIG & TIG Welding Wire

- Export Countries of ERNi-1 MIG & TIG Welding Wire

Metals And Welding Specialities ensures that every spool of ERNi-1 MIG & TIG Welding Wire wire meets international quality specifications, offering consistent chemical composition and excellent performance under both high and low temperature conditions. The filler metal provides outstanding resistance to a range of chemicals including hydroxides, fluorides, and neutral or alkaline salt solutions. Its unique metallurgy allows welders to achieve clean, porosity-free welds with remarkable ductility and toughness, making it a preferred choice for critical fabrication tasks.

One of the key advantages of ASTM ERNi-1 is its exceptional corrosion resistance in caustic and reducing environments, a property that stems from its high nickel content. This makes it particularly suitable for process equipment used in the chemical, food processing, marine, and aerospace industries. It also performs reliably in the manufacturing of heat exchangers, piping systems, storage tanks, and other pressure vessels exposed to corrosive media. The filler metal produces smooth, stable arcs in both MIG (GMAW) and TIG (GTAW) processes, ensuring easy handling and consistent bead appearance.

With UNS N02061 classification, the ERNi-1 wire provides exceptional versatility, allowing it to be used for joining dissimilar metals such as nickel to stainless steel or copper alloys. Its low carbon content prevents carbide precipitation, minimizing the risk of intergranular corrosion. Moreover, the filler metal maintains its mechanical integrity even under elevated temperatures, offering long-term durability and stable performance.

ERNi-1 MIG & TIG Welding Wire in India, ERNi-1 MIG & TIG Welding Wire Manufacturers in India, ERNi-1 MIG & TIG Welding Wire Suppliers in India, ERNi-1 MIG & TIG Welding Wire Stockists in India, ERNi-1 MIG & TIG Welding Wire Exporters in India

As a trusted supplier of specialty welding consumables, Metals And Welding Specialities manufactures and supplies ERNi-1 MIG & TIG Welding Wire filler wire with stringent quality control and precision packaging to ensure optimal weldability and customer satisfaction. Each batch undergoes rigorous testing to verify its composition, mechanical properties, and surface finish. The result is a premium-grade welding wire that guarantees superior weld quality, long service life, and dependable performance in demanding industrial applications.

Metals And Welding Specialities’ commitment to excellence ensures that clients receive not only a product but a complete welding solution that enhances efficiency and productivity across all fabrication environments. When it comes to high-performance nickel alloy welding wires, ERNi-1 MIG & TIG from Metals And Welding Specialities stands as the benchmark for precision, purity, and durability.

-

Specification ERNi-1 MIG & TIG Welding Wire

-

ERNi-1 MIG & TIG Welding Wire Chemical Composition

Element Composition (%) C 0.15 max Mn 1.0 max Fe 1.0 max P 0.03 max S 0.015 max Si 0.75 max Cu 0.25 max Ni 93.0 min Al 1.50 max Ti 2.0 – 3.5 Other 0.50 max -

ERNi-1 MIG & TIG Welding Wire Parameters

Diameter Process Volt Amps (flat) Amps (V/OH) in (mm) .035 (0.9) GMAW 26-29 150-190 Spray Transfer 100% Argon .045 (1.2) GMAW 28-32 180-220 Spray Transfer 100% Argon 1/16 (1.6) GMAW 29-33 200-250 Spray Transfer 100% Argon 1/16 (1.6) GTAW 14-18 90-130 100% Argon 3/32 (2.4) GTAW 15-20 120-175 100% Argon 1/8 (3.2) GTAW 15-20 150-220 100% Argon

People Also Searched

ERNi-1 filler wire, UNS N02061 welding wire, ASTM ERNi-1 specification, Nickel 200 welding rod, Nickel 201 filler metal, MIG welding nickel alloy, TIG welding nickel rod, ERNi-1 composition, Nickel alloy welding electrode, Nickel-based filler metal, Nickel 200 MIG wire, Nickel 201 TIG wire, Welding wire for caustic environments, High purity nickel filler wire, Nickel wire for chemical processing, Nickel alloy for marine welding, AWS A5.14 ERNi-1, Nickel 200/201 joining wire, Corrosion resistant nickel wire, Nickel electrode UNS N02061, Nickel alloy for aerospace, Heat exchanger welding wire, Nickel to stainless welding rod, Nickel filler for pressure vessels, Nickel welding consumables, Nickel alloy joining materials, Industrial nickel welding wire, Nickel-based corrosion resistant alloy, Nickel 200 ERNi-1 wire, Nickel welding wire suppliers, Metals And Welding Specialities nickel filler, High strength nickel MIG wire, TIG wire for nickel alloys, Nickel alloy fabrication materials, Nickel 201 UNS N02061 wire, Nickel alloy ERNi-1 manufacturer, Welding wire for chemical industries

ERNi-1 MIG & TIG Welding Wire, ERNi-1 MIG & TIG Welding Wire Manufacturers, ERNi-1 MIG & TIG Welding Wire Suppliers, ERNi-1 MIG & TIG Welding Wire Stockists, ERNi-1 MIG & TIG Welding Wire Exporters