| Classification | AWS A5.14, ERNiFeCr-2 |

|---|---|

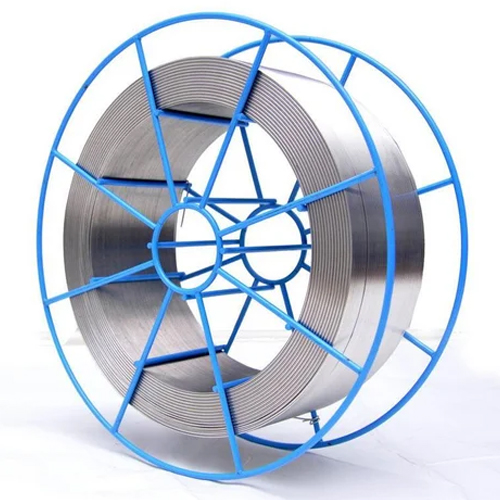

| Form | MIG spools, TIG cut lengths, Reels and Coils |

| Type Of Welding | Inert Gas Welding |

| Standard TIG straight lengths are available | 36” (914 mm) or 39” (1000 mm) lengths. Other lengths available upon request. |

| AWS ERNiFeCr-2 MIG & TIG Metal Application & uses |

|

- 1st Dubhash Lane, Girgaon,

Mumbai-400004

- +91-9920631634

+91 98200 31634

ERNiFeCr-2 MIG & TIG Welding Wire

Metals And Welding Specialities is a trusted supplier and manufacturer of high-quality welding consumables, including ERNiFeCr-2 MIG & TIG Welding Wire wires. These filler materials are engineered for precision welding applications that demand superior corrosion resistance and mechanical strength in extreme service conditions. Classified under UNS N06007 and recognized by ASTM Grade ERNiFeCr-2, this alloy is designed for joining and overlaying nickel-iron-chromium-based materials used in chemical processing, power generation, and aerospace industries.

Table Of Content

- What is ERNiFeCr-2 MIG & TIG Welding Wire?

- Specification of ERNiFeCr-2 MIG & TIG Welding Wire

- Equivalent Grade Of ERNiFeCr-2 MIG & TIG Welding Wire

- Chemical Composition of ERNiFeCr-2 MIG & TIG Welding Wire

- ERNiFeCr-2 MIG & TIG Welding Wire Parameters

- People Searched for ERNiFeCr-2 MIG & TIG Welding Wire

- Supply Cities of ERNiFeCr-2 MIG & TIG Welding Wire

- Export Countries of ERNiFeCr-2 MIG & TIG Welding Wire

The ERNiFeCr-2 filler wire delivers exceptional performance in high-temperature and corrosive environments. Its balanced composition of nickel, iron, and chromium offers excellent oxidation resistance and thermal stability, making it suitable for service temperatures up to 1200°F (650°C). The weld deposits produced using this filler are tough, crack-resistant, and display excellent metallurgical integrity even after prolonged exposure to heat and stress. Whether applied through the MIG (GMAW) or TIG (GTAW) process, this wire ensures smooth arc transfer, low spatter, and a clean, uniform bead profile.

Metals And Welding Specialities ensures that every spool ofERNiFeCr-2 meets stringent quality standards for dimensional accuracy, chemical consistency, and mechanical performance. It is compatible with base metals such as Inconel 690, Inconel 601, and similar nickel-chromium-iron alloys. This filler wire is also widely used for overlay and cladding operations on carbon and low-alloy steels, providing an effective corrosion-resistant surface for components exposed to acids, alkalis, and high-temperature oxidation.

Industries that rely on ERNiFeCr-2 MIG & TIG Welding Wire filler metals include nuclear power plants, petrochemical refineries, and heat exchanger manufacturing units. Its ability to maintain structural integrity under cyclic heating and cooling makes it ideal for welding furnace components, reactor vessels, and piping systems. The weld metal exhibits outstanding resistance to carburization and sulfidation, ensuring long service life and minimal maintenance costs in demanding operational environments.

ERNiFeCr-2 MIG & TIG Welding Wire in India, ERNiFeCr-2 MIG & TIG Welding Wire Manufacturers in India, ERNiFeCr-2 MIG & TIG Welding Wire Suppliers in India, ERNiFeCr-2 MIG & TIG Welding Wire Stockists in India, ERNiFeCr-2 MIG & TIG Welding Wire Exporters in India

At Metals And Welding Specialities, we understand that consistency and reliability are key in welding operations. That’s why our ERNiFeCr-2 welding wires are packaged with moisture-resistant materials and undergo rigorous inspection before dispatch. With our commitment to quality and technical expertise, we provide the perfect solution for industries seeking durability, efficiency, and precision in every weld.

With decades of experience in welding technology and alloy metallurgy, Metals And Welding Specialities continues to serve industries worldwide with dependable, high-performance filler materials. Our ERNiFeCr-2 MIG & TIG Welding Wire wire exemplifies our commitment to precision, durability, and excellence in every weld.

-

Specification ERNiFeCr-2 MIG & TIG Welding Wire

-

Equivalent Grade Of AWS ERCuNi MIG & TIG

Class UNS Oxford Alloys Special Metals ERNiFeCr-2 N07718 Alloy 718 INCOWELD 718 -

ERNiFeCr-2 MIG & TIG Welding Wire Chemical Composition

C Mn Si Cr S P Ni Fe Cu Al Mo Ti Nb+Ta ≤0.08 ≤0.35 ≤0.35 17-21 ≤0.015 ≤0.015 50-55 Rest ≤0.3 0.2-0.8 2.8-3.3 0.65-1.15 4.75-5.5 -

ERNiFeCr-2 MIG & TIG Welding Wire Parameters

Diameter Process Volt Amps Shielding Gas In mm 0.035 0.9 GMAW 26-29 150-190 Spray Transfer100% Argon 0.045 1.2 GMAW 28-32 180-220 1/16 1.6 GMAW 29-33 200-250 1/16 1.6 GTAW 14-18 90-130 100% Argon 3/32 2.4 GTAW 15-20 120-175 100% Argon 1/8 3.2 GTAW 15-20 150-220 100% Argon

People Also Searched

ERNiFeCr-2 filler wire, AWS ERNiFeCr-2, UNS N06007 welding wire, ERNiFeCr-2 TIG rod, MIG filler ERNiFeCr-2, nickel alloy welding wire, ASTM ERNiFeCr-2, Inconel 690 welding wire, nickel-chromium-iron filler metal, corrosion-resistant weld wire, Metals And Welding Specialities ERNiFeCr-2, high-temperature welding wire, ERNiFeCr-2 specification, UNS N06007 composition, ERNiFeCr-2 welding rod, NiFeCr alloy wire, Inconel welding consumables, ERNiFeCr-2 datasheet,ERNiFeCr-2 properties, nickel TIG filler wire, alloy ERNiFeCr-2 chemical composition, UNS N06007 equivalent, ERNiFeCr-2 mechanical properties, ERNiFeCr-2 electrode, ERNiFeCr-2 MIG wire, Metals And Welding Specialities welding products, NiCrFe filler metal, ERNiFeCr-2 density, ERNiFeCr-2 welding applications, ASTM ERNiFeCr-2 standard, UNS N06007 welding rod, ERNiFeCr-2 heat resistance, ERNiFeCr-2 corrosion resistance, NiFeCr-2 filler metal, Metals And Welding Specialities nickel alloy wire, ERNiFeCr-2 for Inconel alloys.

ERNiFeCr-2 MIG & TIG Welding Wire, ERNiFeCr-2 MIG & TIG Welding Wire Manufacturers, ERNiFeCr-2 MIG & TIG Welding Wire Suppliers, ERNiFeCr-2 MIG & TIG Welding Wire Stockists, ERNiFeCr-2 MIG & TIG Welding Wire Exporters