| Classification | AWS A5.14 || EN ISO 18274 |

|---|---|

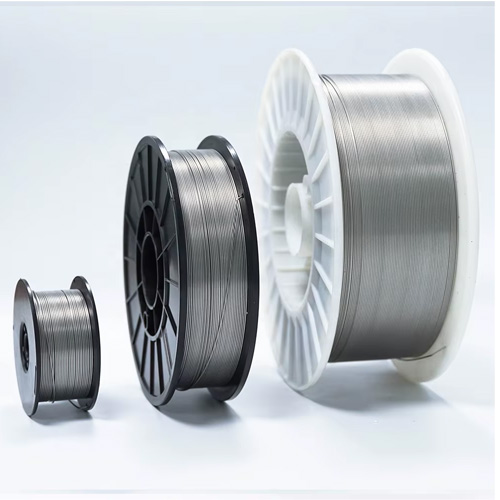

| Form | MIG spools, TIG cut lengths, Reels and Coils |

| Type Of Welding | Inert Gas Welding |

| Standard TIG straight lengths are available | 36” (914 mm) or 39” (1000 mm) lengths. Other lengths available upon request. |

| UTP 6225 AL MIG & TIG Welding Wire Filler Metal Application & uses |

|

- 1st Dubhash Lane, Girgaon,

Mumbai-400004

- +91-9920631634

+91 98200 31634

UTP 6225 AL MIG & TIG Welding Wire

Metals And Welding Specialities proudly presents the UTP 6225 AL MIG & TIG Welding Wire filler wire, a premium aluminum welding electrode engineered to deliver exceptional performance in both MIG welding and TIG applications. This versatile wire is specially formulated to provide superior weld quality on aluminum and its alloys, offering excellent arc stability, smooth deposition, and reliable corrosion resistance in demanding environments. Whether you are fabricating complex structures or repairing lightweight components, this filler metal ensures clean fusion, minimal spatter, and consistent mechanical properties across each joint.

Table Of Content

- What is UTP 6225 AL MIG & TIG Welding Wire?

- Specification of UTP 6225 AL MIG & TIG Welding Wire

- Equivalent Grade Of UTP 6225 AL MIG & TIG Welding Wire

- Chemical Composition of UTP 6225 AL MIG & TIG Welding Wire

- UTP 6225 AL MIG & TIG Welding Wire Parameters

- People Searched for UTP 6225 AL MIG & TIG Welding Wire

- Supply Cities of UTP 6225 AL MIG & TIG Welding Wire

- Export Countries of UTP 6225 AL MIG & TIG Welding Wire

At the core of UTP 6225 lies the ASTM A5.10 classification, and it conforms to UNS A94043 standards. The product is also commonly referred to by its universal standard name ER4043, reflecting its status in the industry. These specifications guarantee that Metals And Welding Specialities delivers a wire that meets recognized global benchmarks for aluminum filler metals. The chemical formulation is optimized to balance silicon content for fluid weld puddle control and tensile strength to provide welds that are robust under stress.

When using UTP 6225 filler wire, welders benefit from the wire’s compatibility with gas-shielded arc welding, particularly noticeable when switching between MIG and TIG processes. The welding efficiency remains high, and the resulting weld bead exhibits clean appearance, reduced porosity, and excellent intergranular stability. Thanks to its refined metallurgy and consistent diameter tolerances, UTP 6225 helps reduce defects like undercut or lack of fusion, ensuring repeatable quality even in critical weld zones.

In situations demanding wide temperature ranges or cyclic loading, UTP 6225 maintains mechanical integrity and resists common issues like hot cracking and oxidation. Its predictable behavior during weld pool formation makes it suitable for joining various aluminum alloys, including 6xxx and 5xxx series, when compatibility criteria are met. The filler wire’s ease of feeding into both MIG torches and TIG torch wire feeders helps weld shops maintain productivity without frequent wire changes or parameter adjustments.

UTP 6225 AL MIG & TIG Welding Wire in India, UTP 6225 AL MIG & TIG Welding Wire Manufacturers in India, UTP 6225 AL MIG & TIG Welding Wire Suppliers in India, UTP 6225 AL MIG & TIG Welding Wire Stockists in India, UTP 6225 AL MIG & TIG Welding Wire Exporters in India

Metals And Welding Specialities supports this product with detailed technical datasheets and application guidance. Our team assists in selecting optimal shielding gas mixes, welding current settings, and preheat or post-weld treatments to achieve the best results. With UTP 6225, fabricators and service shops gain a reliable tool in their aluminum fabrication toolkit—a filler wire intended for serious industrial demands, marine repairs, automotive bodywork, and lightweight structural assemblies.

In summary, the UTP 6225 AL MIG & TIG Welding Wire wire by Metals And Welding Specialities delivers precision, consistency, and durability. It is compliant with ASTM A5.10, designated UNS A94043, and widely known as ER4043 in universal standards. For engineers, welders, and QA professionals seeking a dependable aluminum filler metal that works across MIG and TIG processes, this offering represents a high-performance solution tuned for professional use.

-

Specification UTP 6225 AL MIG & TIG Welding Wire

-

Equivalent Grade Of UTP 6225 AL Coated Electrodes

Class UNS Oxford Alloys DIN ERNiCrMo-10 N06022 Oxford Alloy 622 2.4602 -

UTP 6225 AL MIG & TIG Welding Wire Chemical Composition

Element C Si Cr Mo Nb Fe Ni Composition (%) ≤ 0.02 ≤ 0.2 22.0 9.0 3.5 < 1.0 Balance -

UTP 6225 AL MIG & TIG Welding Wire Parameters

Welding Process Shielding Gas Polarity Wire Diameter (mm) Current (A) Voltage (V) MIG (GMAW) Argon + 2% CO₂ or Argon + 2% O₂ DCEP (+) 0.8 – 1.2 80 – 220 18 – 28 TIG (GTAW) 100% Argon DCEN (−) 1.6 – 3.2 (Rod) 50 – 160 As required by arc length

People Also Searched

ER4043 filler wire, UNS A94043 welding wire, ASTM A5.10 aluminum wire, aluminum MIG filler, aluminum TIG filler, aluminum welding electrode, aluminum silicon wire, high quality aluminum filler, 4043 aluminum wire, UTP 6225 wire, MIG TIG aluminum wire, aluminum welding rod, ER-4043 spool, aluminum welding consumables, aluminum weld alloy 4043, MIG AL wire 4043, TIG AL wire 4043, UNS A9 4043 wire, aluminum welding electrode 4043, filler metal for aluminum 4043, ER 4043 MIG wire, ER 4043 TIG wire, aerospace aluminum filler, structural aluminum weld wire, marine aluminum filler, corrosion resistant aluminum wire, aluminum welding material 4043, aluminum filler metal alloy, Al-Si welding filler, aluminum welding rod 4043, UTP aluminum filler, premium aluminum filler 4043, MIG aluminum electrode 4043, TIG aluminum electrode 4043, aluminum joining wire 4043.

UTP 6225 AL MIG & TIG Welding Wire, UTP 6225 AL MIG & TIG Welding Wire Manufacturers, UTP 6225 AL MIG & TIG Welding Wire Suppliers, UTP 6225 AL MIG & TIG Welding Wire Stockists, UTP 6225 AL MIG & TIG Welding Wire Exporters