| Classification | ENiCrMo-14 |

|---|---|

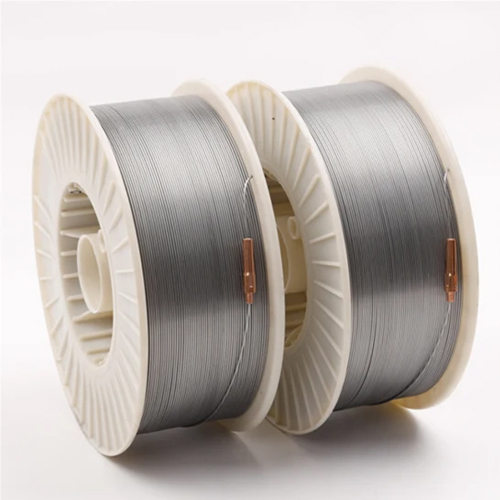

| Form | MIG spools, TIG cut lengths, Reels and Coils |

| Type Of Welding | Inert Gas Welding |

| Standard TIG straight lengths are available | 36” (914 mm) or 39” (1000 mm) lengths. Other lengths available upon request. |

| AWS ENiCrMo-14 MIG & TIG Metal Application & uses |

|

- 1st Dubhash Lane, Girgaon,

Mumbai-400004

- +91-9920631634

+91 98200 31634

ENiCrMo-14 MIG & TIG Welding Wire

Metals And Welding Specialities manufactures and supplies high-quality ENiCrMo-14 MIG & TIG Welding Wires designed for superior performance in demanding industrial applications. This nickel-chromium-molybdenum alloy filler metal offers outstanding corrosion resistance, high-temperature strength, and excellent weldability. Classified under UNS N06686 and conforming to ASTM Grade ERNiCrMo-14, it is engineered to deliver reliable results in aggressive chemical environments and high-stress operational conditions.

Table Of Content

- What is ENiCrMo-14 MIG & TIG Welding Wire?

- Specification of ENiCrMo-14 MIG & TIG Welding Wire

- Equivalent Grade Of ENiCrMo-14 MIG & TIG Welding Wire

- Chemical Composition of ENiCrMo-14 MIG & TIG Welding Wire

- ENiCrMo-14 MIG & TIG Welding Wire Parameters

- People Searched for ENiCrMo-14 MIG & TIG Welding Wire

- Supply Cities of ENiCrMo-14 MIG & TIG Welding Wire

- Export Countries of ENiCrMo-14 MIG & TIG Welding Wire

The ENiCrMo-14 alloy provides exceptional protection against localized corrosion such as pitting and crevice attack, making it an ideal choice for welding materials exposed to seawater, oxidizing acids, and strong reducing agents. It performs exceptionally well in industries such as chemical processing, marine engineering, pollution control, and offshore structures where maximum durability and resistance to corrosive elements are critical.

Metals And Welding Specialities’ ERNiCrMo-14 MIG & TIG wires offer stable arc characteristics and excellent bead appearance. The filler metal ensures clean, smooth welds with minimal spatter and superior fusion. Its composition of nickel, chromium, molybdenum, and tungsten enhances mechanical strength and metallurgical stability even under severe thermal cycling. This makes it suitable for joining high-alloy steels and nickel-based alloys used in heat exchangers, piping systems, and pressure vessels.

The UNS N06686 wire maintains mechanical integrity at elevated temperatures, supporting long-term performance in oxidation and carburization-prone atmospheres. Its low carbon content reduces carbide precipitation, thereby preventing intergranular corrosion. Whether used for overlaying, cladding, or joining similar or dissimilar metals, ENiCrMo-14 delivers dependable metallurgical compatibility and outstanding weld joint strength.

ENiCrMo-14 MIG & TIG Welding Wire in India, ENiCrMo-14 MIG & TIG Welding Wire Manufacturers in India, ENiCrMo-14 MIG & TIG Welding Wire Suppliers in India, ENiCrMo-14 MIG & TIG Welding Wire Stockists in India, ENiCrMo-14 MIG & TIG Welding Wire Exporters in India

As a trusted manufacturer, Metals And Welding Specialities adheres to stringent quality standards and uses advanced production techniques to ensure consistent product quality. Each spool of ENiCrMo-14 MIG & TIG Welding Wire wire undergoes rigorous inspection and testing to meet international specifications and client expectations. The product’s versatility, combined with its resistance to oxidizing and reducing chemicals, makes it a preferred choice across various industrial sectors seeking long-lasting welding solutions.

Choosing Metals And Welding Specialities ENiCrMo-14 MIG & TIG wires ensures performance reliability, metallurgical precision, and exceptional corrosion protection for critical welding projects. With its robust mechanical properties, high weld efficiency, and compatibility with advanced nickel alloys, this filler metal stands as a benchmark of quality and dependability in modern fabrication environments.

-

Specification ENiCrMo-14 MIG & TIG Welding Wire

-

ENiCrMo-14 MIG & TIG Welding Wire Chemical Composition

Element Composition (%) C 0.02 max Mn 1.0 max Fe 5.0 max P 0.02 max Cu 0.50 max Ni Remainder Ti 0.25 max Cr 19.0 – 23.0 S 0.02 max Si 0.25 max Mo 15.0 – 17.0 W 3.0 – 4.4 Other 0.50 max -

ENiCrMo-14 MIG & TIG Welding Wire Parameters

Diameter of Wire Voltage (V) Flat Vertical and Overhead 3/32 inches (2.4mm) 20 – 23 70 – 80 65 – 80 1/8 inches (3.2mm) 21 – 24 80 – 110 75 – 95 5/32 inches (4.0mm) 22 – 25 120 – 160 Not recommended 3/16 inches (4.8mm) 23 – 25 170 – 190 Not recommended

People Also Searched

ERNiCrMo-14 welding wire, UNS N06686 filler metal, ENiCrMo-14 electrode, ERNiCrMo-14 TIG rod, ENiCrMo-14 MIG wire, Metals And Welding Specialities nickel alloy wire, ASTM ERNiCrMo-14 filler metal, nickel chromium molybdenum alloy wire, Inconel 686 welding wire, nickel-based TIG wire, corrosion-resistant filler metal, NiCrMo welding rod, UNS N06686 welding alloy, ENiCrMo-14 specifications, nickel alloy MIG wire, high-temperature welding wire, chemical processing weld wire, marine alloy welding rod, nickel chromium alloy filler, heat exchanger welding wire, alloy 686 filler metal, ENiCrMo-14 application, NiCrMo alloy weld rod, ASTM ERNiCrMo-14 composition, UNS N06686 chemical properties, alloy 686 TIG rod, corrosion-resistant nickel filler, welding wire for seawater applications, overlay welding alloy, Metals And Welding Specialities ENiCrMo-14, NiCrMo-14 chemical resistance, high-strength weld filler, nickel alloy welding electrode, industrial welding wire manufacturer, AWS ENiCrMo-14 TIG filler metal.

ENiCrMo-14 MIG & TIG Welding Wire, ENiCrMo-14 MIG & TIG Welding Wire Manufacturers, ENiCrMo-14 MIG & TIG Welding Wire Suppliers, ENiCrMo-14 MIG & TIG Welding Wire Stockists, ENiCrMo-14 MIG & TIG Welding Wire Exporters