| Classification | SFA/AWS A5.14 : ERNiCr-3, EN ISO 18274 : S Ni 6082 (NiCr20Mn3Nb) |

|---|---|

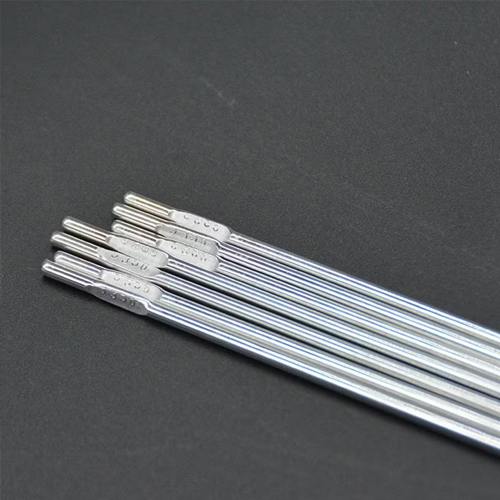

| Form | Welding Electrode, Welding Rods |

| Type Of Current | Direct Current Electrode Positive (DCEP) |

| Diameters | 3/32”, 1/8”, 5/32”, 3/16” or 2.5mm, Ø 3.2mm, Ø 4.0mm, Ø 5.0mm |

| Size | 2.0mm ∞ 5.0mm |

| AC/DC+ | 50-80, 80-110, 100-135, 140-180 |

| Welding Positions | All positions 5/32” & 3/16” recommended for use in flat & horizontal positions only (F, V, OH, H) |

| AWS A5.5, E9018-B3 Coated Electrodes Application & uses |

|

- 1st Dubhash Lane, Girgaon,

Mumbai-400004

- +91-9920631634

+91 98200 31634

EXATON Ni72hp Welding Electrodes

The Exaton Ni72Hp Welding Electrodes from Metals And Welding Specialities are designed for precision, performance, and reliability in demanding industrial welding applications. Engineered with advanced nickel-based alloy composition, these electrodes deliver exceptional strength, corrosion resistance, and metallurgical stability, even in harsh operating conditions. Classified under UNS N06072 and conforming to ASTM A5.11 ENiCrFe-7 standards, Exaton Ni72Hp offers a superior solution for joining and repairing nickel-chromium-iron alloys and dissimilar metal combinations.

Table Of Content

- What is Exaton Ni72Hp Welding Electrodes?

- Specification of Exaton Ni72Hp Welding Electrodes

- Equivalent Grade Of Exaton Ni72Hp Welding Electrodes

- Chemical Composition of Exaton Ni72Hp Welding Electrodes

- Exaton Ni72Hp Welding Electrodes Parameters

- People Searched for Exaton Ni72Hp Welding Electrodes

- Supply Cities of Exaton Ni72Hp Welding Electrodes

- Export Countries of Exaton Ni72Hp Welding Electrodes

Built to withstand extreme environments, Exaton Ni72Hp Welding Electrodes are particularly suited for welding components exposed to high-temperature oxidation, carburization, and thermal fatigue. They ensure a stable arc, low spatter, and smooth weld bead profile, minimizing post-weld finishing time. This makes them a preferred choice across industries such as petrochemical, marine, power generation, and oil & gas, where weld integrity and corrosion protection are critical.

The high nickel content in Exaton Ni72Hp electrodes promotes strong resistance to chloride-induced stress corrosion cracking and crevice corrosion, making them ideal for fabrication and maintenance in environments containing seawater, acids, and other corrosive agents. Their coated design enhances deposition efficiency and arc stability, providing excellent control even during positional welding.

At Metals And Welding Specialities, every batch of Exaton Ni72Hp Welding Electrodes undergoes strict quality testing to meet international standards for chemical composition, mechanical properties, and weldability. The electrodes exhibit outstanding performance on both AC and DC current, ensuring consistent penetration and fusion without porosity or cracking. Whether you’re joining Inconel®, stainless steels, or heat-resistant alloys, these electrodes deliver precision and reliability you can trust.

Exaton Ni72Hp Welding Electrodes in India, Exaton Ni72Hp Welding Electrodes Manufacturers in India, Exaton Ni72Hp Welding Electrodes Suppliers in India, Exaton Ni72Hp Welding Electrodes Stockists in India, Exaton Ni72Hp Welding Electrodes Exporters in India

The metallurgical compatibility of Exaton Ni72Hp electrodes allows for seamless joining between dissimilar materials, including nickel-chromium alloys and ferritic or austenitic steels. This makes them indispensable in high-performance fabrication projects, such as turbine components, furnace parts, chemical processing equipment, and offshore installations. The resulting welds maintain high tensile strength, creep resistance, and excellent ductility, even after prolonged service at elevated temperatures.

Choosing Exaton Ni72Hp Welding Electrodes from Metals And Welding Specialities means choosing durability, precision, and quality assurance. Engineered to meet global industrial requirements, these electrodes embody a perfect balance between innovation and proven performance, making them an essential consumable for professionals seeking long-lasting weld integrity and consistent results.

-

Specification Exaton Ni72Hp Welding Electrodes

-

Equivalent Grade Of AWS ENiCrMo-4 Coated Electrodes

Class UNS Oxford Alloys BOHLER E9018-B3 W53018 Alloy 9018-B3 BOHLER FOX P 22 -

Exaton Ni72Hp Welding Electrodes Chemical Composition

C Mn Si S P Ni Cr Mo Al Cu N Nb Ti Co Fe Nb+Ta <0.02 3.2 0.01 0.003 <0.003 73 20 0.01 0.09 0.01 0.03 2.2 0.31 <0.02 ≤1 2.5 -

Exaton Ni72Hp Welding Electrodes Parameters

Wire Diameter Current Voltage Wire Feed Speed 0.8 mm 40-120 A 15-19 V 4.0-8.0 mm/min 1.0 mm 60-220 A 15-28 V 4.0-12.0 mm/min 1.2 mm 150-260 A 24-29 V 3.0-10.0 mm/min 1.6 mm 230-350 A 25-30 V 3.0-5.0 mm/min

People Also Searched

Exaton Ni72Hp welding electrodes, UNS N06072 electrode, ENiCrFe-7 welding rod, Ni-based coated electrode, high nickel alloy electrode, nickel chromium iron electrode, Inconel welding electrode, dissimilar metal welding rod, corrosion-resistant welding electrode, ASTM A5.11 electrodes, heat-resistant nickel electrode, nickel alloy repair welding, EXATON Ni72hp filler metal, high-temperature welding electrode, marine welding electrode, petrochemical welding rods, power plant maintenance electrodes, offshore welding consumables, NiCrFe-7 alloy electrode, ENiCrFe-7 welding specification, UNS N06072 chemical composition, ENiCrFe-7 mechanical properties, EXATON nickel electrode supplier, Metals And Welding Specialities electrodes, high-strength nickel electrodes, stainless to nickel welding rod, heat exchanger welding consumables, Ni72hp electrode datasheet, nickel-based SMAW electrodes, corrosion-resistant filler metals, industrial welding electrodes, high-temperature nickel alloy rods, precision welding electrodes, ENiCrFe-7 AWS classification, nickel superalloy welding, UNS N06072 electrode supplier, ENiCrFe-7 electrode manufacturer, nickel welding consumables India.

Exaton Ni72Hp Welding Electrodes, Exaton Ni72Hp Welding Electrodes Manufacturers, Exaton Ni72Hp Welding Electrodes Suppliers, Exaton Ni72Hp Welding Electrodes Stockists, Exaton Ni72Hp Welding Electrodes Exporters