| Specification | Details |

|---|---|

| Product Name | XHD 2222 |

| Type | Coated Electrode |

| Standard Classification | AWS A5.1 E7018 / IS 814 – ER 4211X |

| Coating Type | Low Hydrogen, Iron Powder |

| Current Type | AC / DC+ |

| Typical Applications | Structural Steel, Bridges, Pressure Vessels, Pipelines |

| Tensile Strength | ≥ 490 MPa |

| Yield Strength | ≥ 400 MPa |

| Elongation | ≥ 22% |

| Impact Strength | ≥ 47 J at 0°C |

| Operating Current (A) | 90–150 (depending on electrode diameter) |

| Electrode Diameter (mm) | 2.5, 3.15, 4.0, 5.0 |

| Welding Position | All Positions (except vertical down) |

| Typical Polarity | DCEP (DC+) |

| Storage | Keep dry, re-dry at 300–350°C for 1 hour before use |

- 1st Dubhash Lane, Girgaon,

Mumbai-400004

- +91-9920631634

+91 98200 31634

XHD 2222 Welding Electrodes

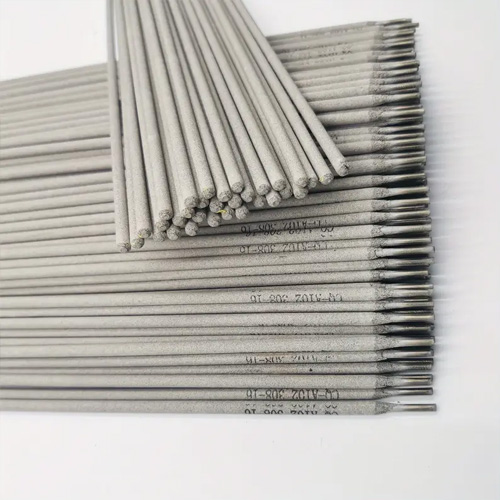

At Metals And Welding Specialities, we proudly present the XHD 2222 Welding Electrodes, engineered for demanding welding and repair tasks across heavy industry. Our XHD 2222 electrode offers an ideal solution when you require a high-strength, corrosion-resistant weld metal that performs under thermal cycling and stress. When selecting electrodes for critical repair or joining, the XHD 2222 stands out for its versatility, toughness, and metallurgical stability.

Table Of Content

- What is XHD 2222 Welding Electrodes?

- Specification of XHD 2222 Welding Electrodes

- Equivalent Grade Of XHD 2222 Welding Electrodes

- Chemical Composition of XHD 2222 Welding Electrodes

- XHD 2222 Welding Electrodes Parameters

- People Searched for XHD 2222 Welding Electrodes

- Supply Cities of XHD 2222 Welding Electrodes

- Export Countries of XHD 2222 Welding Electrodes

The XHD 2222 electrode (commonly known under the universal designation “E Ni-1” per DIN EN standards) is a nickel-based rutile-basic coated stick electrode. Its weld deposit is rich in Ni-Cr-Fe-Mn alloying elements, delivering superior resistance to oxidation, scaling, and stress‐induced cracking. Typical tensile strength reaches 90,000 psi (≈ 630 MPa) and yield strength is about 65,000 psi (≈ 450 MPa), while elongation stays in the 30–35 % range even in heavy section welds.

In service, XHD 2222 excels in joining carbon steels, heat-treatable steels, cryogenic steels, nickel alloys, and dissimilar combinations thereof. Its deposit shows minimal residual stress and reduced susceptibility to embrittlement from sigma phases, carbides or nitrides. The electrode performs reliably under both AC and DC+ current modes, with typical amperage ranges of 80–160 A depending on diameter (e.g. 2.5–4.0 mm)

Although XHD 2222 does not map directly to a single ASTM “Grade” (since it is a high-nickel alloy electrode rather than a carbon steel welding consumable), it is often referenced in specifications as E Ni-1 (or sometimes under custom nickel‐based filler classifications). For clarity and purchasing specifications, its UNS (Unified Numbering System) designation is UNS N02201 (a typical Ni–Cr–Fe weld alloy in this class). In practice, when specifying in drawings or procurement documents, many users will call it “ASTM E Ni-1 / UNS N02201 – XHD 2222 Coated Electrode.”

XHD 2222 Welding Electrodes in India, XHD 2222 Welding Electrodes Manufacturers in India, XHD 2222 Welding Electrodes Suppliers in India, XHD 2222 Welding Electrodes Stockists in India, XHD 2222 Welding Electrodes Exporters in India

Metals And Welding Specialities ensures that every batch of XHD 2222 Welding Electrodes is rigorously quality tested for coating integrity, moisture content, and weld metal chemistry. We recommend preheating only when required by the base metal (particularly when joining crack‐sensitive steels or very thick sections), controlling heat input, and employing short arc technique with stringer beads to manage distortion. Interpass cleaning and light peening may further enhance crack resistance and deposit integrity.

Clients deploying XHD 2222 typically include heavy equipment repair shops, furnace maintenance teams, kiln shell repair specialists, and petrochemical plant welders. It is frequently used for flame-hardening equipment, heat-treating racks & trays, kiln tyre repairs, ingot tongs, continuous casting molds, cryogenic service parts, and dissimilar metal joints requiring high corrosion resistance .

Clients deploying XHD 2222 typically include heavy equipment repair shops, furnace maintenance teams, kiln shell repair specialists, and petrochemical plant welders. It is frequently used for flame-hardening equipment, heat-treating racks & trays, kiln tyre repairs, ingot tongs, continuous casting molds, cryogenic service parts, and dissimilar metal joints requiring high corrosion resistance.

-

Specification XHD 2222 Welding Electrodes

-

XHD 2222 Welding Electrodes Parameters

Parameter Value Product Xuper / EutecTrode XHD 2222 (XHD-2222) Coating / Type Rutile-basic, coated stick electrode (SMAW) Classification DIN/EN approx. E Ni1 Weld metal type / main alloying Ni-Cr-Fe-Mn (nickel base alloy) Typical tensile strength 90,000 psi (≈ 621 MPa) Typical yield strength 65,000 psi (≈ 448 MPa) Typical elongation (A) Minimum ~40% Typical hardness (BHN) ≈ 180 BHN Deposition / output High deposition; typical output ~150% Recommended polarity / current AC or DC+ (DC electrode positive) Recommended amperage by diameter 2.4 mm (3/32") : 80–120 A

3.2 mm (1/8") : 110–160 A

4.0 mm (5/32") : 150–190 APrimary applications Welding/repair of heavily stressed parts, heat-treat trays & baskets, kiln tires, continuous casting molds, joining dissimilar steels

People Also Searched

XHD 2222 electrode, E Ni-1 electrode, UNS N02201 welding rod, nickel alloy coated electrode, NiCrFeMn electrode, nickel welding stick N02201, XHD 2222 stick electrode, Ni-Cr welding electrode, N02201 filler metal, E Ni-1 AWS, nickel coated electrode, nickel repair rod, high nickel welding rod, XHD2222 electrode supplier, N02201 electrode price, nickel electrode for dissimilar welding, corrosion resistant weld rod Ni base, XHD 2222 weld rod specification, Ni-Cr-Fe rod electrode, E Ni-1 filler metal, nickel hardface electrode, N02201 welding consumable, XHD 2222 repair rod, Ni-1 stick electrode, welding rod for nickel steels, nickel coated stick rod, Ni-Cr repair welding rod, nickel electrode for cryogenic steels, electrode for dissimilar steels, high temperature nickel rod.

XHD 2222 Welding Electrodes, XHD 2222 Welding Electrodes Manufacturers, XHD 2222 Welding Electrodes Suppliers, XHD 2222 Welding Electrodes Stockists, XHD 2222 Welding Electrodes Exporters